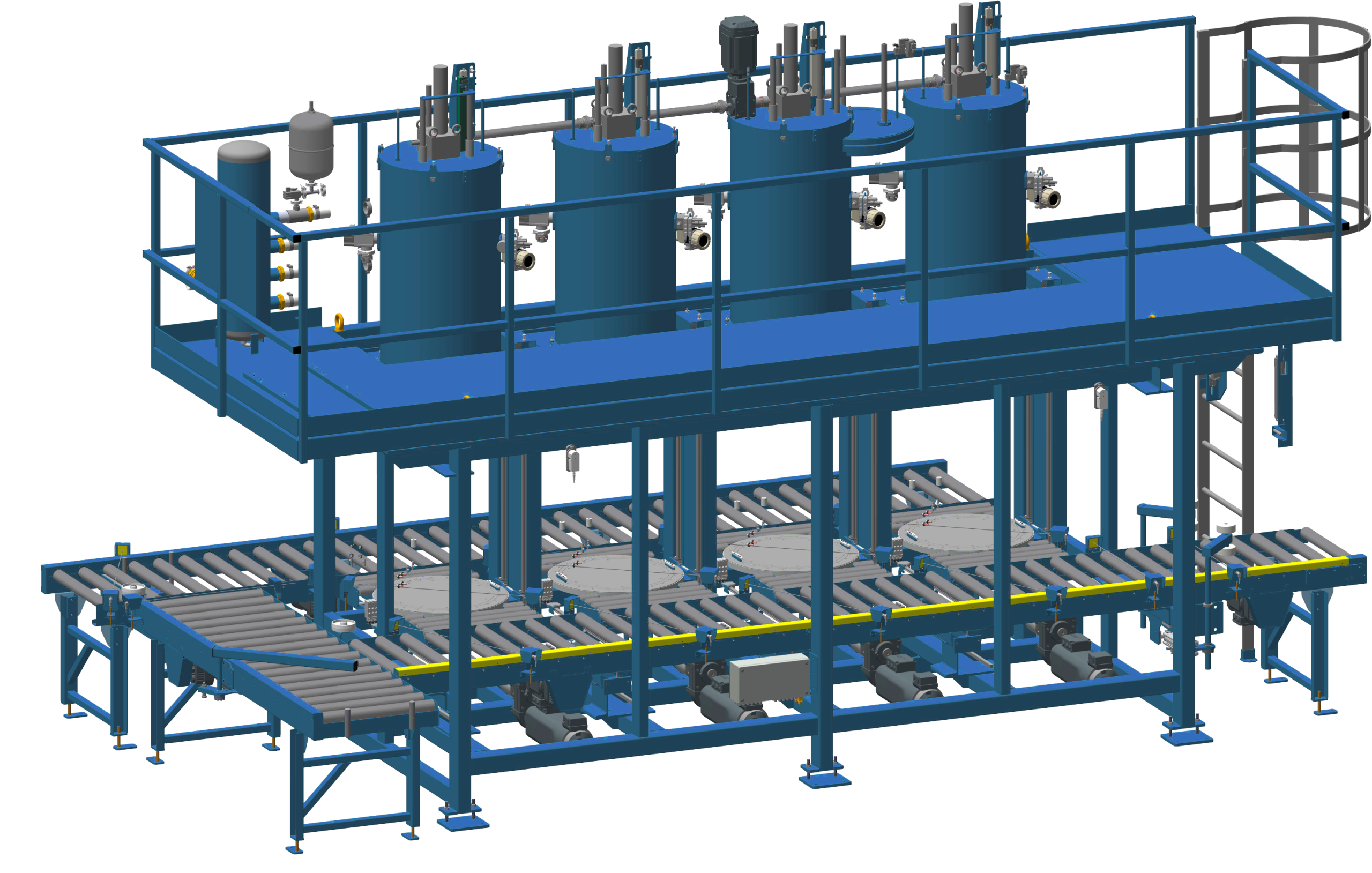

Hybrid Leak Tester

= VACUUM LEAK TESTER

Improve your quality control with our advanced vacuum hybrid leak tester. This state-of-the-art machine is engineered for precise drum testing of both tight head as open head steel drums using vacuum technology.

Our fully automatic system seamlessly integrates into your production line, efficiently transporting drums through single or multiple testing stations, achieving cycle times of up to 800 drums per hour.

Our system operates on the principle of choked flow, where at a specific absolute pressure ratio between inlet and outlet pressure, the flow velocity at an orifice reaches sonic velocity, resulting in a constant mass flow rate.

+ HELIUM DETECTION ADD-ON

While the vacuum leak tester is already a proven solution for fast and accurate testing of steel drums, the hybrid leak tester with the Helium Detection Add-On improves its performance and precision, without replacing the core system.

With a technical system upgrade including extra pumps and a mass spectrometer, the leak testing machine can reach a detection sensitivity of 0.0001 mbar·L/s, meeting the highest standards in the industry.

This Helium Detection add-on integrates seamlessly without any impact on the machine’s original functionality. It makes the hybrid system fully scalable , allowing operation in vacuum-only, helium-only or combined modes.

Benefits of Vacuum Technology

-

CONTAMINATION

- Evacuating the air around the drum in the vacuum chamber, rather than pumping air into the drum, helps prevent contamination inside the drum.

-

AIR DISPLACEMENT

- Minimizing the volume around the drum in the vacuum chamber, results in less air displacement and therefor shorter operational time for the pump and faster stabilization before measuring.

-

TEMPERATURE

- The reduced air flow combined with vacuum instead of positive pressure, results in less kinetic energy of the particles and makes the system less susceptible to temperature influences.

-

FAST AND RELIABLE

- As a result of the vacuum technology based on the choked flow principle, our system achieves rapid and reliable measurements. This enhances repeatability, sensitivity, and processing speed without the need for a reference drum or (re)calibration.

-

FLEXIBILITY

- By sealing the tight head drum on the bung holes, this machine can process drums without requiring additional caps or screwed bungs. This gives the customer flexibility to integrate the leak tester on different locations within their factory layout.

-

OPERATIONAL COSTS

- Less air displacement and fast, reliable measurements reduce the operational time and capacity of the pump. Combined with the redundancy of inert mediums like Helium, this machine offers significant cost savings.

Downloads

Vacuum leak tester brochure

Vacuum leak tester brochure